What Are Different Types of Flexible Electrical Conduit?

Leave a CommentDifferent Types of Flexible Electrical Conduit

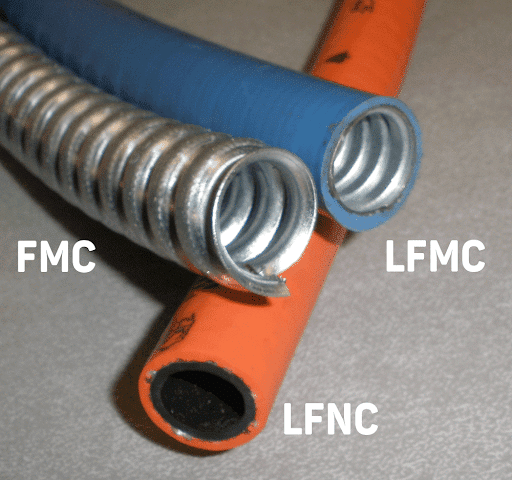

Flexible conduit is described as a raceway for electrical conductors or wiring. Material, assembly and use are described in the NEC. Here are the most common types of flexible electrical conduit.

1. Flexible Metal Conduit (FMC)

This type of electrical conduit is lightweight, durable and easy to install. This flexible metal conduit is made of a helically wound strip of metal (galvanized steel or aluminum) that provides strength and flexibility while protecting wire. It is recommended for concealed or exposed dry areas. It bends easily to fit around corners and obstacles, making it suitable for surface-mounted installations. For options available from ANAMET Electrical, Inc. see FMC Conduit.

Some of the common applications include:

- Industrial and commercial settings: This conduit is used in buildings, electric motor connection, elevators, escalators and chair lifts, where wiring is not exposed to water.

- Residential settings: They can be commonly used in homes, especially for wiring appliances like washers, dryers, refrigerators, heaters and air conditioners.

2. Liquid Tight Flexible Metal Conduit (LFMC)

As the name implies, this is one of the flexible electrical conduit types that work exceptionally well in wet environments. It has a metal core with an extruded thermoplastic cover to make a liquid tight conduit. Galvanized steel is often used for the stripwound core with an integral bonding wire. However, NEC approved stainless steel in the stripwound core in 2023 when installed with a separate grounding conductor or bonding jumper.

A variety of thermoplastic materials are approved by UL for conduit jackets. These thermoplastic jackets have heat-, cold-, corrosion-, prolonged UV- and static electricity-resistant properties.

The following are some common applications for LFMC conduit:

- Outdoor and underground installations: Liquid-tight conduit is suitable for areas that may be exposed to moisture or water, such as irrigation systems, air conditioners or outdoor lighting. UL listed conduit suitable for burial in the earth or in concrete is marked with DIR BURIAL or DIRECT BURIAL. For more information, see What is Direct Burial?

- Hazardous locations: Since they offer protection against moisture and corrosion, UL listed, liquid tight conduit is approved for use in Class I Div. 2 Hazardous Locations exposed wiring might cause danger.

3. Liquid Tight Flexible Non-Metallic Conduit (LFNC)

As the name implies, this is one of the flexible electrical conduit types that works exceptionally well in wet environments. It is PVC extruded as liquid tight conduit.

There are two varieties of LFNC, Types A and B. Two layers of flexible PVC sandwich a layer of continuous nylon knit cord in LFNC Type A. Type B is a continuous coil of PVC in a smooth PVC jacket. For more information about the differences between these LFNC Types available from ANAMET Electrical, Inc., see LFNC Types.

The following are some common applications for this type of conduit:

- Outdoor and underground installations: Liquid tight non-metallic conduit is suitable for areas that may be exposed to moisture or water, such as irrigation systems, air conditioners or outdoor lighting.

- Hazardous locations: Since they also offer protection against moisture and corrosion, UL listed liquid tight conduit is approved for use in Class I Div. 2 Hazardous Locations exposed wiring might cause danger.

- Jacket options: Halogen Free and fire resistant jackets are available for conduit installation in hot, confined work spaces.

Choose the Right Conduit Size

Consider electrical conduit size to keep connection easy.

- UL listed flexible conduit is available from ANAMET Electrical in diameters from ⅜ inch to 2 inches.

- Choose conduit and fittings that suit the application, so the conduit can be connected to a power panel or junction box through standard knockout holes.

A rule of thumb is for three or more wires to fill 40% or less of the conduit volume, to allow for wire fishing and flexibility. More wires or cable make conduit rigid and hard to bend.

Contact Anamet Electrical Inc. For All Your Flexible Conduit Needs

At Anamet Electrical Inc., we offer a wide range of flexible electrical conduit types to meet your needs. Our products are designed to connect and protect electrical wiring easily and effectively. Contact us today for more information.