Architects, engineers, and construction (AEC) professionals help resolve environmental challenges. Ongoing research and development in building materials and methods promote environmental safety. This is done by informed selection and installation of sustainable materials – like electrical products made from environmentally safe or non-toxic materials.

Conduit and fittings that don’t contain harmful and dangerous substances support this work. Furthermore, this promotes energy efficiency and avoids harmful emissions into the atmosphere.

Choosing manufacturers complying with environmental safety standards makes material selection easier. For instance, ANAMET Electrical, Inc. works with national and international associations to sustain and extend safety standards. With this in mind, our products are rigorously tested to ensure that all electrical conduit solutions don’t contain harmful toxins such as lead.

The Dangers of Lead-Sheathed Copper Cables

From the late 1800s to the 1960s, lead was used to shield telephone cables from electromagnetic interference. Although telecommunication companies stopped using lead-sheathed copper wire in the 1950s, some installations were abandoned in place. The cables were considered inert and unlikely to cause harm if left buried in the ground. Unfortunately, underground lead sheathing is exposed to groundwater.

Telecommunication companies that were potentially associated include:

- AT&T

- Verizon

- Lumen Technologies

- Frontier Communications

Research shows lead exposure is a considerable health hazard. News items point up other sources of lead such as lead paint and lead plumbing pipes. Currently, there are 48 million housing units in the United States exposed to lead, due to poor maintenance. Lawsuits are ongoing to reduce lead exposure.

Lead Remediation May Cost Billions of Dollars

New Street Research (NSR) estimated clean-up costs for lead-wrapped cables could surpass $60 billion. That high cost does not address potential health hazards. This estimate is based on discussions with incumbent local exchange carriers (ILECs).

NSR noted AT&T has the highest exposure, totaling 23.186 million housing and business units, followed by Verizon and Lumen. NSR Lead U.S. Analyst Jonathan Chaplin estimated labor costs for removing the lead sheathed cable are the same as installing optical fiber, excluding splicing costs. Unfortunately, it is unclear if corporations, consumers or taxpayers will quickly reduce this hazard.

Using Lead-Free Conduit and Fittings for a Safer and Healthier Environment

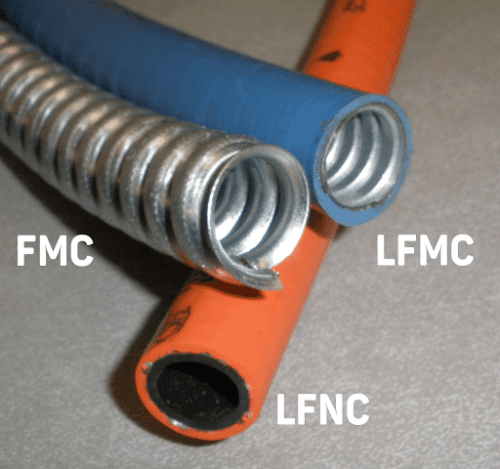

Fortunately, ANAMET Electrical ANACONDA SEALTITE® conduit products conform to the National Electrical Code (NEC) requirements for safe wiring connection. These connection solutions range among metallic, non-metallic, and specialty options that meet or exceed safety requirements of the AEC community.

In addition, the ANACONDA SEALTITE® electrical conduit conforms to the following international standards for health and safety:

- REACH SVHC (Substances of Very High Concern) Compliance

- RoHS3 (Restrictions on Hazardous Substances) Compliance

- Conflict Minerals Compliance

- WEEE (Waste Electrical and Electronic Equipment Directive) Compliance

- EPA Toxic Substances Control Act (TSCA) Compliance

ANAMET Electrical continues research to develop conduit options that surpass safety standards while extending wiring protection. We update our documentation online to sustain our commitment to avoiding use of dangerous materials.

Safe Electrical Conduit Solutions for a Sustainable Future

Striving to improve the world, AEC professionals need materials that won’t damage the environment. Choosing a conduit and fittings that don’t pose health and environmental risks is a step toward creating sustainable buildings and infrastructure.

Protect wiring, data networks and control runs by specifying UL-listed ANACONDA SEALTITE® conduit. Visit Deltek Specpoint to get MasterSpec content for ANACONDA SEALTITE® flexible conduit.

If you want to know more about ANAMET Electrical ANACONDA SEALTITE® electrical conduit, please contact us today. You may also request a quote, and our team will develop a solution tailored to your needs!