Services Overview

Liquid tight, flexible, electrical conduit connects and protects electrical wiring. The liquid tight jacket and fittings prevent intrusion of moisture, contamination, corrosion, stress and strain. The conduit has proven to be a reliable and durable shield for people from burns, shock and other injury from uncontrolled electricity. Conduit is tested for safety, in compliance with Underwriters’ Laboratories, National Fire Prevention Association and National Electrical Code standards. We work to make sure ANACONDA SEALTITE® conduit is safe, flexible and durable.

ANAMET Electrical, Inc. is a recognized leader in production of safe, flexible, liquid-tight electrical wiring conduit. We sustain regulatory recognition for our products, resulting in new solutions that ensure safe use of electricity. Pioneering products, such as ANACONDA SEALTITE® conduit, are used worldwide in commerce and industry. During World War II, liquid tight cable was required for safe operation of electrical equipment in harsh conditions. Electrical distribution was enabled and secured using our products. April 18, 1949, SEALTITE® was listed by Underwriters’ Laboratories, the first liquid tight conduit available to protect civilian electrical systems. Since then, conduit was developed to provide durable connection in extreme temperatures, radiated environments and corrosive conditions, including direct burial in the ground.

Additional services are offered at our factory in Mattoon, Illinois, enabling special applications for flexible conduit. Please contact us about your specific needs.

Cutting

Correct cutting of flexible conduit ensures secure, liquid tight, connection. A square cut ensures continuity of the ground path for UL listed electrical conduit. This requires careful measuring, cutting with a bandsaw and finishing of the cut end. ANAMET Electrical can cut conduit to custom lengths within tight tolerances.

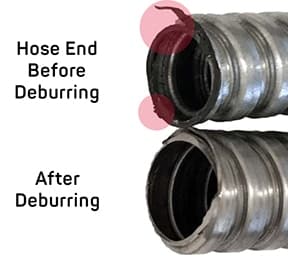

Deburring

After cutting flexible conduit, it is critical to debur or finish the conduit, removing sharp edges and burrs.

Rough or sharp edges are smoothed, making conduit safer to handle and easier to install in a fitting.

Burnishing

Custom Marking

Passivation

When iron compounds remain on the surface of stainless steel, it increases the chance of corrosion. Passivation is the process that removes the iron deposits. The process uses chemical dissolution with nitric or citric acid to remove the iron to prevent corrosion while maintaining the integrity of the stainless steel.

Braiding

Custom Color Conduit

Color jackets on conduit can be aesthetically appealing and provide quick visual identification of products, brands or applications. NEMA guidelines designate some colors for specific types or purposes for wiring, such as designating high-voltage, architectural, healthcare, data communications, security and optical fiber conduit. Color coding streamlines cable tracing, saving time and money. We stock conduit with black and gray jackets. Custom color jackets can be applied in a variety of durable formulations.

Special Liquid-Tight Covers

Whether your application requires PVC, TPE, TPU or silicone liquid-tight covers, ANAMET makes conduit with these jacket formulations. Liquid tight conduit protects against dust and liquids indoors, outdoors or in corrosive conditions. Flexible, liquid tight conduit is the standard choice for connection of outdoor air conditioning units, water pumps and electrical equipment exposed to water, weather, vibration, contamination and corrosive chemicals.

Custom Services at ANAMET Electrical

ANAMET Electrical adds value beyond what is available in imported or off-the-shelf, commodity conduit. Research and development efforts at our factory enable continuous improvement in materials, finishes, electrical conduit, fittings and stripwound hose. Participation in industry bodies and sustained compliance with regulatory oversight keeps us current with commercial and industrial needs. We ensure high-quality products endure, competitively, in applications worldwide.

Contact us if you need a reliable design solution for protecting wiring, cables or instrumentation from harsh operating conditions. ANAMET Electrical can partner with you as your electrical conduit supplier, so you can concentrate on other product features. For more information, or to get started on your electrical wiring conduit project, contact us or request a quote today.