How Do You Choose a Conduit Jacket?

Leave a CommentYou want a safe, liquid tight, flexible and durable electrical conduit? Meeting liquid tight, flexible and durable requirements for electrical conduit is just the start.

There are options you may not have considered. These conduit jacket options are now available from ANAMET Electrical, Inc.

- High flexibilty

- Temperature resistance

- Chemical, oil, and corrosion resistance

- Anti-Static

- Food Grade (NSF and FDA compliant)

- Prolonged UV (sunlight) exposure resistance

- Halogen Free (no chlorine or fluorine)

Conduit jackets provide a liquid tight barrier around wiring. The jacket blocks dust, oil and water intrusion that can degrade or damage electrified cable and wiring. A flexible conduit jacket also conforms to liquid tight fittings for an end to end seal against intrusion.

Old liquid tight conduit was made with lead, asbestos or other toxic substances. However, conduit from ANACONDA SEALTITE® now meets WEEE RoHS and REACH approval for safe use worldwide.

Anamet Electrical, Inc. offers advanced solutions engineered to meet the rigorous demands of food and pharmaceutical processing, building and construction, telecommunications and factory automation industries.

Considerations for Selecting an Electrical Conduit Jacket

High Flexibility

If your conduit must withstand vibration or frequent bending, non-UL listed Type MTC can stand up to the abuse.

How flexible does your conduit need to be? The flexibility of conduit is the result of the assembled conduit core and the jacket. Lower bend radius values are the significant numbers to compare among conduit options.

Even if buried underground or embedded in concrete it pays to use a conduit that can take a little shaking or quaking. UL (Underwriters’ Laboratories) listed ANACONDA SEALTITE® electrical conduit is suitable for Direct Burial and in concrete.

Temperature Resistance

If you are not sure how hot or cold the temperatures will become where you must protect wiring, you can’t go wrong in selecting a conduit that is durable in extreme temperatures.

Chemical, Oil and Corrosion Resistance

Before you purchase a large quantity of conduit, always test a conduit sample by exposure to the unique chemistry of the location where you must protect wiring. Although most PVC conduit will resist common household chemicals, there are industrial chemicals that nothing can withstand in combination.

If you need to protect wiring from cutting oil, grease and other lubricants, UL listed conduit must meet oil resistance requirements to wear the UL approval mark.

If exposed to salt spray, consider stainless steel core conduit in three different jackets:

- SS-UA standard UL 360 listed

- SS-HTUA High Temperature UL 360 listed

- SS-ZHUA Zero Halogen UL 360 listed

Anti-Static

In dusty locations, where there is a lot of particulate matter in the air, consider Type ASUA conduit. This conduit jacket meets the NEN-EN-IEC 600079-0 Section 26-13 anti-static surface resistivity requirement of less than 1 billion (thousand million) Ohms. This is a safety feature to reduce or avoid static electricity buildup and discharge.

Food Grade (NSF and FDA Compliant)

In food and pharmaceutical production, Food Grade equipment wiring must be protected from frequent decontamination and washdown. NSF approved conduit and fittings are suitable for these conditions due to anti-bacterial jacket material and high quality seals against intrusion.

Prolonged UV (Sunlight) Exposure Resistance

For longtime outdoor use, select a jacket that stands up to UV (ultraviolet or sunlight) exposure. Type UVUA ANACONDA SEALTITE® withstood over 3.8 times the UV Weatherometer exposure of UL 360 approved conduit. UV resistance prevents the jacket from cracking or fading over time, sustaining a liquid tight barrier against dirt or liquid intrusion.

Halogen Free/Zero Halogen

In confined areas, with limited or no reliable ventilation, install a Halogen Free or Low Smoke conduit that will not produce toxic chlorine or fluorine fumes in case of fire.

Flexible Electrical Conduit

ANAMET Electrical, Inc. offers a comprehensive range of electrical conduit solutions and related accessories designed for flexibility, safety and ease of use. Secure your connections.

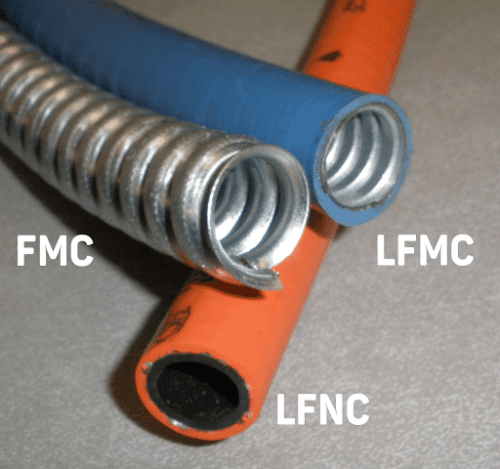

PVC Non-Metallic Conduit

- Offers a balance of flexibility and durability

- Ensures liquid tightness for indoor and outdoor use

Liquid Tight, Flexible Metal Conduit

- Superior flexibility for challenging installations

- Maintains durability and liquid tightness in confined or exposed areas

- Excellent resistance to heat, chemicals and weathering, suitable for confined, exposed or hazardous locations

- Can be routed easily around corners or fit in confined spaces without compromising protection

Both PVC Non-Metallic Conduit and Liquid tight, Flexible Metal Conduit deliver reliable flexibility, durability and liquid tightness. These attributes ensure ease of installation, longevity and effective protection for cable and wiring.

ANACONDA SEALTITE® from Anamet Electrical, Inc. Delivers

ANAMET Electrical delivered innovative conduit solutions since 1908. Our ongoing work with manufacturers, builders and international regulations provides us with a depth of experience meeting and exceeding user’s needs.

If you need help selecting conduit to meet your project parameters, please contact us today.