What Is a Flexible Electrical Conduit?

Electrical conduit is a raceway with a circular cross-section that routes and protects electrical wiring in residential, industrial and commercial applications. A flexible electrical conduit is a durable tube that protects electrical wiring in enclosed areas with hard turns, such as in water heaters or lighting fixtures. Materials used to manufacture conduit include metal, fiber or plastic. Installed by electricians at the installation site, electrical conduit fittings and liquid tight jackets protect the wiring from stress, strain, corrosion, heat and moisture.

Conduit reliably protects electrical wiring systems from exposure and wear, shielding people from injury, equipment damage and electric shock. Local building codes and the National Electrical Code (NEC) indicate where and how conduit should be installed for safe electrical operation.

ANAMET Electrical, Inc. has been manufacturing durable, liquid tight, flexible electrical conduit systems since 1908. Our proprietary techniques and tooling enable our customers to safely connect and protect electrical wiring systems in the air, at sea, and on land. Our conduit is rigorously tested for various industrial, residential, and commercial applications.

Since 1949, we have produced Anaconda Sealtite® conduit types listed for safe use according to Underwriters Laboratories (UL) standards. This trademarked conduit currently protects and connects optical fibers, cables and electrical wiring worldwide.

ANAMET Electrical, Inc. is the world’s largest supplier and manufacturer of liquid tight flexible metal conduit. Learn more about the different types and advantages of flexible electrical conduit.

Reasons to Install Flexible Conduit Systems

Flexible conduit effectively protects wiring from harsh operating conditions. Here are some reasons to install flexible conduit systems:

- As pull outlets for installed conductors

- Connect sections of rigid conduit

- Connect junction boxes to electrical equipment

- Provide visible transitions and routing for critical circuits

- Connect to wired devices and lighting fixtures

- Provide access to conductors for maintenance and system upgrades

- Make 90° bends in conduit runs

Types of Flexible Electrical Conduit Available from ANAMET Electrical, Inc.

Electrical conduit is classified by the materials used, wall thickness, tubing size and mechanical stiffness. Corrosion resistance and cost are determining factors when selecting conduit.

Here are the main types of flexible electrical conduit available from ANAMET Electrical, Inc.

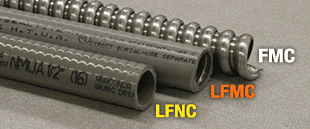

Flexible Metal Conduit (FMC)

Standard FMC is suitable for dry, indoor locations, and it is often used for short runs. The stripwound metal hose is flexible, suitable for installations requiring tight bends in a confined space, where rigid conduit will not fit.

Liquid Tight Flexible Metal Conduit (LFMC)

Liquid tight, flexible metal conduit has a polymer coating and requires sealed threaded fittings for a liquid tight seal. Sizes range from 3/8″ to 4”. This conduit is frequently installed outdoors, in wet operating conditions or burial underground. A variety metal cores are available for corrosion resistance or electromagnet shielding. A variety of polymer jackets are available, meeting Food Grade, confined space, Halogen Free or high temperature requirements.

Liquid Tight Flexible Non-Metallic Conduit (LFNC)

Sealtite® non-metallic conduit consists of a continuous coil of PVC encased inside flexible PVC material that resists oil, heat and chemical breakdowns. The non-conductive hose uses non-metallic or liquid tight metal connectors for quick installation. This conduit is flame-retardant, durable and UV-resistant. Manufactured using PVC, an LFNC has a smooth interior and exterior surface and is resistant to oils and UV rays. Our Sealtite® LFNC is certified by UL standard 1660, compliant with RoHS requirements, and meets NEC code. The crush-resistant conduit is lightweight and can waterproof whole wiring systems requiring liquid tight conduit fittings. This polymer conduit is frequently installed outdoors where it is exposed to sunlight and extreme weather while connecting outdoor equipment to power supply, such as air conditioning units.

Advantages & Benefits of Flexible Electrical Conduit

Flexible electrical conduit is the preferred choice for contractors in both residential and commercial applications. Some of the advantages of flexible conduit include:

- Protects conductors from moisture, corrosion, impact, and chemicals

- Long service life

- Easy installation

- Prevents accidental damage to wiring insulation

- Available in different sizes and types to accommodate any system design or conductor

- Easily modified

- Protects against explosions and fire in National Electrical Code Hazardous Locations

- Resistance to heat and cold for installation in low or high ambient temperature ranges

- Extremely flexible with tight bend radii

- Crush-resistant

Flexible electrical conduit can be buried in concrete or underground. A metallic conduit creates an effective shield for protecting sensitive circuits against electromagnetic interference (EMI). Conduit jackets are resistant to radiation, oil, heat and cold. Extruded polymer jackets are available in a vareity of colors.

Flexible Electrical Conduit From ANAMET Electrical, Inc.

Flexible electrical conduit are integral parts of a system operating under harsh conditions. Knowing the types of electrical conduit available, their benefits, and the reasons to install them, you can make a more informed decision for your application.

As a leading provider of flexible electrical conduit, ANAMET Electrical offers:

- Liquid Tight Flexible Metal Conduit (UL listed and unlisted)

- Liquid Tight Flexible Non-Metallic Conduit

- Flexible Conduit Fittings

- Specialty Conduit

Additional services are offered at our factory, allowing for greater customization for your flexible conduit systems. These services include:

- Cutting to specific lengths

- Burnishing

- Deburring

- Custom print on the polymer jacket

- Braiding

- Custom color jacket

- Liquid tight polymer conduit jacket

- Extreme temperature jackets

- Extra flexible core and jacket configurations

- Light weight or shielding conduit cores

Contact us to discuss your specific needs, or request information about our extensive product line.