Why are engineers switching to certain types of conduit?

Leave a CommentEngineers focus on delivery of effective design solutions within a budget and schedule. While simple electrical jobs cost only a few hundred dollars, larger installations may be more expensive due to the specific demands, needs or harsh operating conditions where electrical supply must be sustained and protected.

National Electrical Code (NEC) changes and new products open opportunities for engineers to improve protection of electrical wiring. Here are conduit options engineers consider for protecting electrical wiring.

Understanding Electrical Conduit

Electrical conduit is critical for protecting electrical wiring at varying current and voltage levels in a variety of service conditions. Conduit may be rigid, flexible, metal, non-metallic or liquid tight.

Choosing the right conduit for operating conditions is crucial for successful completion of a project, passing inspection, turning over the project to an owner’s use and avoiding callbacks to repair faulty systems during and after the warranty period.

Engineering Considerations for Conduit

Rigid and flexible conduit types are available for protecting wiring. Each has attractive features and drawbacks. Below we’ll look at features that help engineers choose an electrical conduit to meet requirements.

Conduit may be rigid or flexible. Here are a few considerations affecting choice.

Rigid Conduit Options

Rigid conduit has a great reputation for use in the construction industry. Engineers choose this type of conduit if installation can be done and forgotten.

- Rigid metal (galvanized steel or stainless steel) conduit withstands harsh environments. The cost and labor for installing this option is a drawback. Bending conduit requires attention to control drawings and special tools for correct installation. Larger diameter bent conduit must be ordered in advance of installation for a correct fit around structures or machinery. Lighter weight, bendable conduit has little effective structural strength and is electrically conductive, so fasteners and seals are important for continuous and reliable service.

- Rigid non-metallic (polyvinyl chloride/PVC, HDPE, or other non-metallic material) conduit has a lower cost and ease of installation, but it is less durable at installation and afterwards. Most are rated for direct burial and in concrete. It has little effective structural strength and is not electrically conductive. Fasteners and seals are important for continuous and reliable service. Moisture intrusion at joints and difficulties with corner installation are drawbacks.

NOTE: For cost consideration, non-metallic rigid conduit may cost the least for initial installation, but replacement costs after destructive wear outweighs the initial cost savings.

Flexible Conduit Options

Since the 1920s, Underwriters’ Laboratories (UL) approved flexible conduit has proven effective for protecting residential and industrial wiring. Engineers choose UL listed, flexible conduit if installation must be inspected and modified due to changes in layout or power demand.

Due to variations in electrical conductivity of flexible conduit, code limits on more than six feet of length between junction boxes and grounding or bonding points is a consideration, if not a drawback. Electrical code allows for a variety of core and jacket materials. Flexible conduit is commonly used for electrical service amperage below 60 amps and under 1000 volts (dependent on conduit diameter and rating).

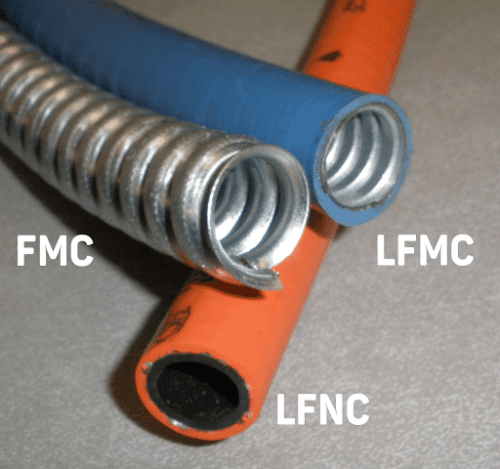

- Bare Flexible conduit (metal (FMC)) is suitable for confined spaces in walls, under floors or in overhead spaces where wiring needs to go around corners. This is often called Flex or Greenfield. It is suitable only for dry locations.

- Liquid tight conduit (metal (LFMC) or non-metallic (LFNC)) is suitable for confined spaces exposed to moisture, dirt or oil. UL listed fittings between conduit and junction boxes secure wiring from moisture and dust intrusion, enabling an effective path for grounding or bonding of metal conduit.

As the name suggests, flexible conduit can bend and flex without breaking, allowing for bending around corners without special tools. UL listed liquid tight conduit (LFMC) is also suitable for direct burial and in concrete.

NOTE: Some installations demand a combination of rigid metal and liquid tight flexible metal conduit to protect wiring in confined spaces. Shown here is an example of rigid metal and liquid tight conduit assembled for routing wiring around corners.

Some Additional Options to Consider

Recent electrical code updates allow more electrical conduit metal and jacket options.

- Stainless steel core metal and non-metallic flexible conduit, since it is not an effective conductor, requires a separate grounding conductor or bonding jumper. This may require three conducting wires instead of just two in the conduit.

- ANACONDA SEALTITE® Food Grade conduit and fittings meet CFR 21 and NSF 51 food safety requirements. This is suitable for connecting electricity to meat processing, pharmaceutical production and food service equipment.

- Halogen Free and Low Smoke liquid tight flexible conduit meets national safety requirements for installation in tunnels and confined spaces.

- Extreme temperature liquid tight flexible conduit is rated for high and low temperatures for installation in refrigerated or high heat locations including outdoors in harsh operating conditions.

- ANACONDA SEALTITE® Type ASUA conduit is UL listed and meets NEN-EN-IEC-600079-0 Section 26-13 anti-static surface resistivity requirement, suitable for protecting wiring in dusty locations.

- ANACONDA SEALTITE® Type UVUA conduit is UL listed and has extended resistance to UV (sunlight) degradation of the PVC jacket. This conduit jacket is suitable for outdoor use in prolonged sunlight or indoor use near UV sources.

Contact Anamet Electrical, Inc. To Choose The Right Conduit For Your Project

We are the world’s largest manufacturer and supplier of liquid tight, flexible conduit. Contact us when you are in doubt about which type of conduit to use for your project. Our team of experts will help guide you through the selection process and ensure that you choose the best conduit for your specific needs. Our goal is to help engineers deliver reliable service that stands the test of time.